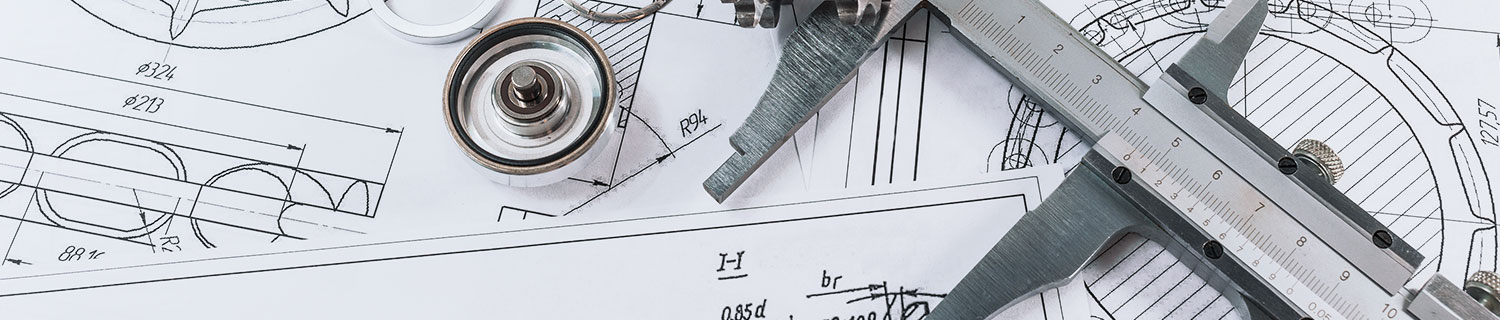

Design, sampling and testing

All work of BERGER Group within product design and development, as well as production of special tools, is carried out in close coordination with the customers. Checks, necessary for the approval of clamping rings, are also carried out directly in-house. For this purpose, special test methods have been developed, e.g. drop tests, pressure tests or leak tests, which comply consistently with UN standards. The developed products are released with the participation of the customer.

All new developments are characterized by many years of experience, a large reservoir of existing tools and the resulting different possibilities for design. This sampling procedure involves, if necessary, a plurality of prototypes being created until a final decision regarding release can be made by the customer.

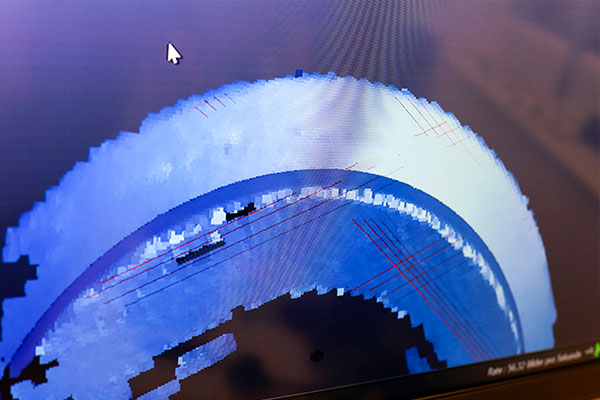

CAD design of moulding tools

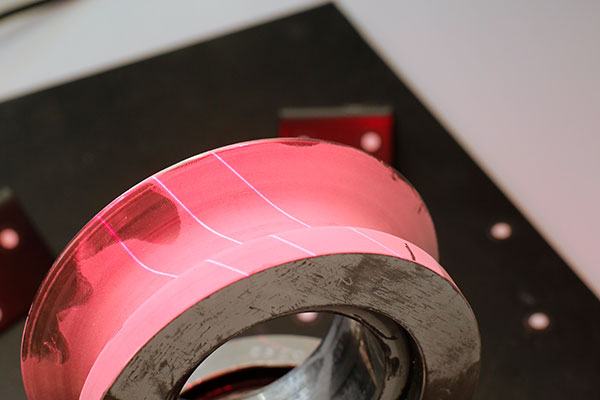

Profile tool

BERGER Group also communicates with its customers at a CAD-supported level. BERGER has modern design tools (CAD systems) at its disposal to support the customer in development work as best as possible. Accordingly, data formats may be exchanged at all times. Especially in the case of new developments, BERGER’s well-trained engineers work hand in hand with its customers. The aim is to ensure the customer can use the product successfully, and possibly even achieve legal approvals (UN).

Global

Global